On November 22-24, the three-day SWOP 2023 Packaging World (Shanghai) Expo (hereinafter referred to as SWOP) was grandly held at the Shanghai New International Expo Center, attracting numerous business visitors and actively presenting smart achievements in the packaging field, injecting fresh energy into the new journey of the plastic industry towards high-end manufacturing.

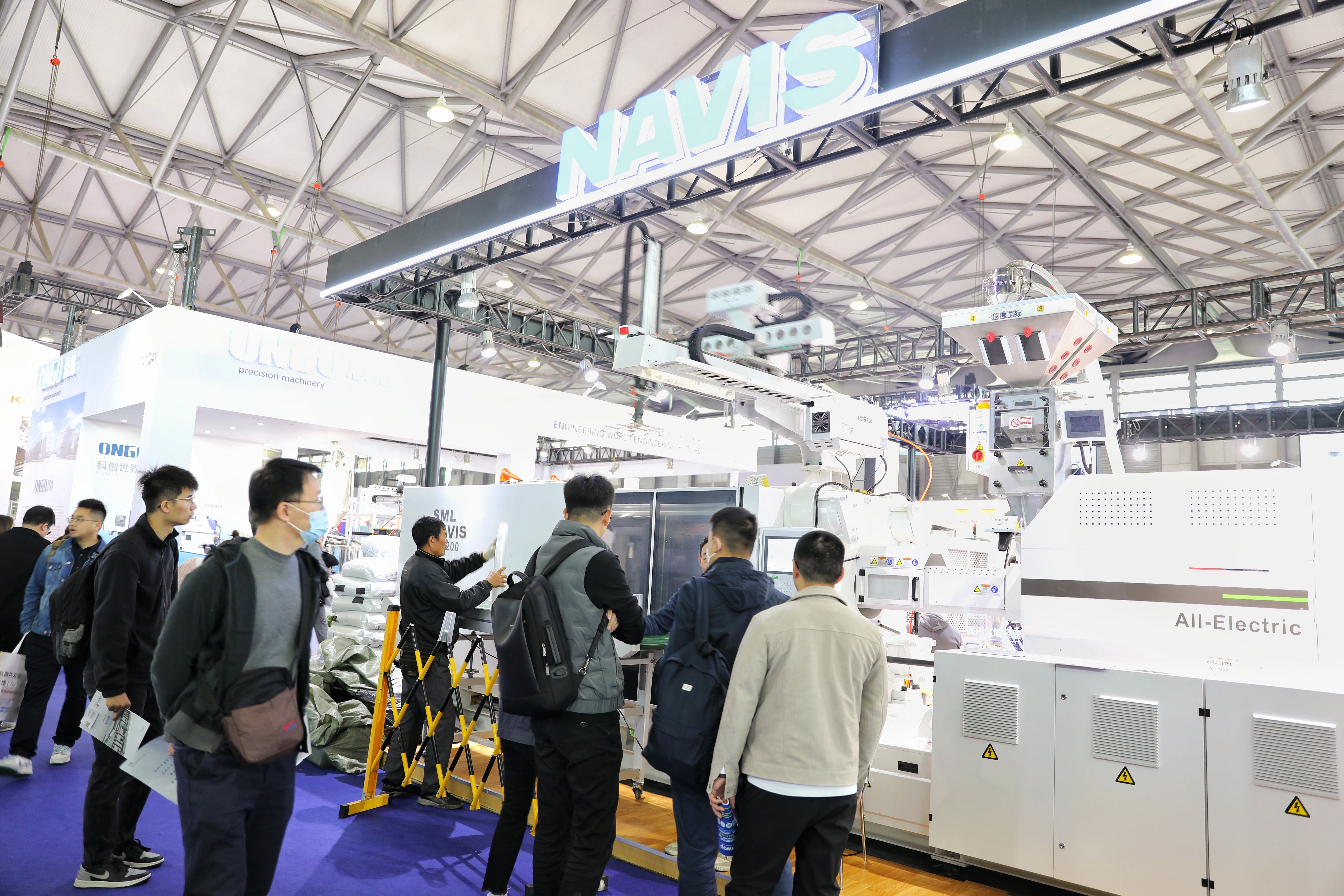

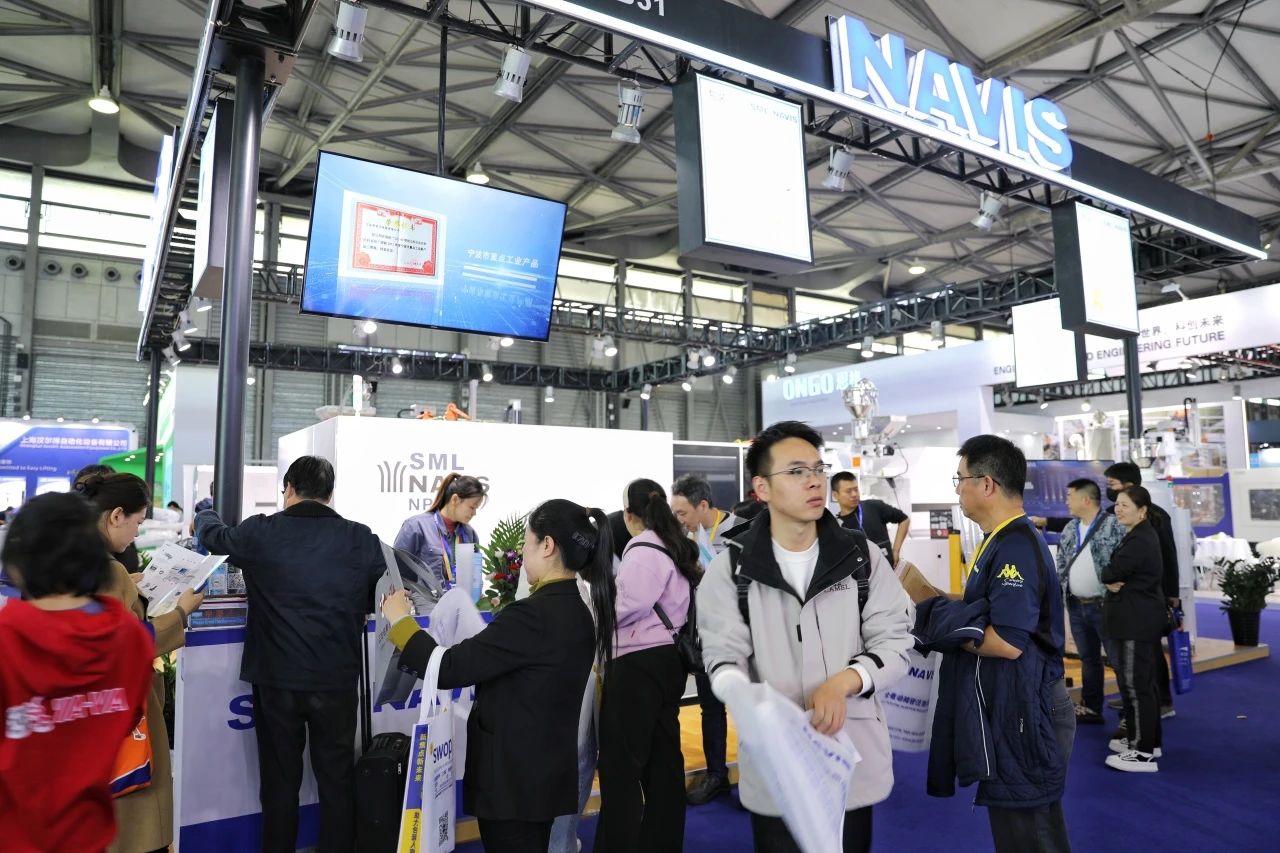

At this exhibition, Speyer unveiled its NAVIS fully electric injection molding machine at booth N1B51. We demonstrated on-site the injection molding solutions for the film attached yogurt cup and 700ml hot drink cup, focusing on the two models of NAVIS NP-3800 and NP-4200. Together with on-site customers, we explored the current development status and new opportunities in the packaging industry.

At this exhibition, Speyer unveiled its NAVIS fully electric injection molding machine at booth N1B51. We demonstrated on-site the injection molding solutions for the film attached yogurt cup and 700ml hot drink cup, focusing on the two models of NAVIS NP-3800 and NP-4200. Together with on-site customers, we explored the current development status and new opportunities in the packaging industry.

Integrate resources and stimulate new impetus for business development

1NP-3800

At this exhibition, NAVIS brought the NP-3800 high-speed model and demonstrated the efficient molding solution for yogurt cups with inner membrane adhesive on site. By working together with labeling machines, auxiliary machines, and conveyor belts, this solution can achieve rapid production in 1 output of 16, 4.3 seconds. Excellent performance provides more possibilities for injection molding production, empowers the development of plastic circular economy, and helps customers accelerate on the green and low-carbon development track.

Product Name: Yogurt Cup with Inner Membrane Sticker Application Model: NP-3800 Forming Chamber Number: 1 Out of 16 Product Raw Material: PP Product Weight per gram: 5.67g Forming Cycle: 4.3s

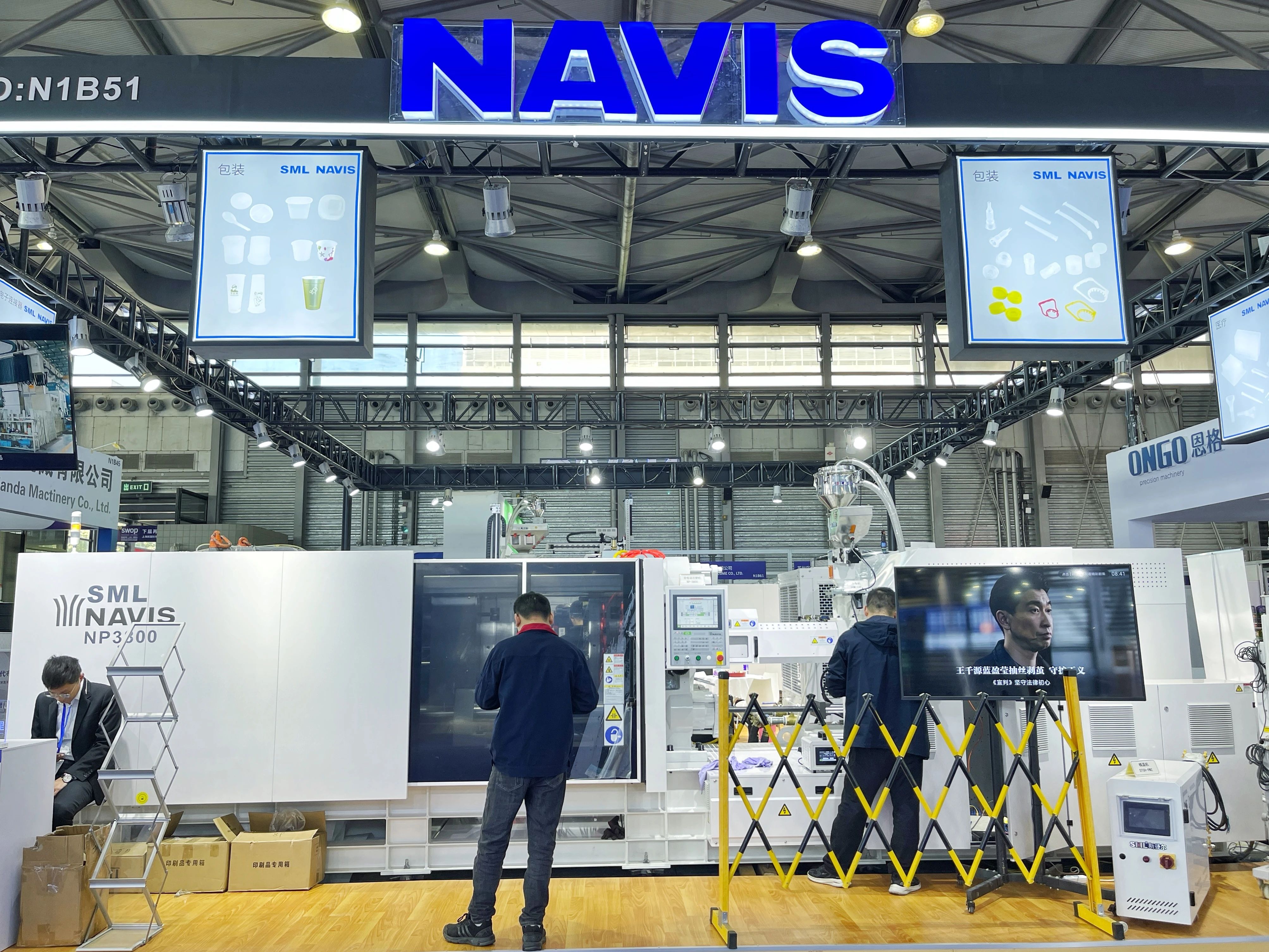

2NP-4200

NP-4200 demonstrated on-site the injection molding solution for 700ml hot drink cups. This solution uses PP raw materials to achieve 1-out 9, with a product weight of 24g and a molding cycle of about 6s. The whole machine is equipped with a servo motor, and the injection speed can reach 500-600mm/s, achieving optimization and improvement in both molding quality and production efficiency.

Product name: 700ml hot drink cup Application model: NP-4200 Forming chamber number: 1 out of 9 Product raw materials: PP Product weight per gram: 24g Forming cycle: 6s

The NAVIS fully electric injection molding machine, with its energy-saving, efficient, and stable characteristics, is equipped with multiple intelligent technologies to achieve digital fine control, improve production efficiency for customer production and operation, and empower customers with high-quality development. Customer satisfaction has always been the driving force behind Smanel's persistent progress. In the future, Smile will continue to pursue technological breakthroughs and innovation, providing customers with more efficient and reliable overall solutions, as well as comprehensive professional services to continuously empower every customer and move towards the future of the industry. SWOP is still in full swing, and we look forward to meeting you at N1B51 to jointly promote the prosperity and development of China's plastic industry!